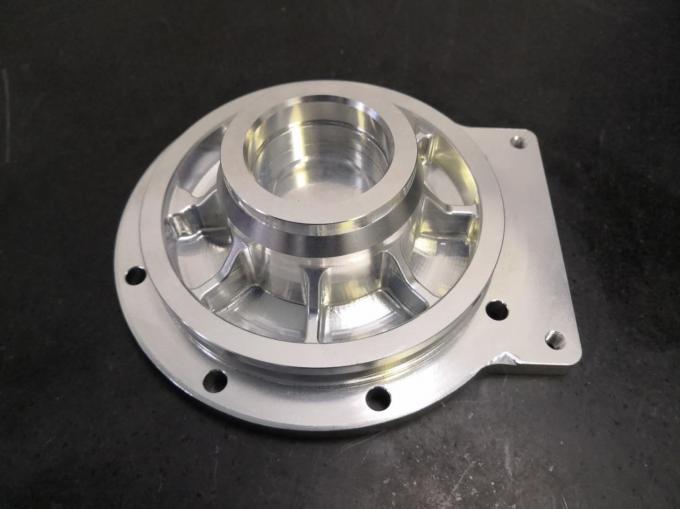

3 Aixs CNC Auto Parts Car Engine Components Hydraulic Pump Electric Motors

3 Aixs CNC Auto Parts Car Engine Components Hydraulic Pump Electric Motors Description

| Cnc Machining Or Not: | 3 Aixs CNC Multiple Machining | Material: | Aluminum7075 |

|---|---|---|---|

| Application: | Electric Motors For Electric Bus | Service: | OEM ODM CNC Machining Parts |

| Quality: | According Tolerance,100% Inspection With QC Report,ISO Certified | Sample: | 3-10 Working Days |

| High Light: | cnc car parts, precision automotive components | ||

3 Aixs CNC Auto Parts Car Engine Components Hydraulic Pump Electric Motors

OEM CNC auto parts Automotive spare parts custom car parts Engine Parts Hydraulic pump parts Bearing parts

Material: AL7075 Surface:Anodizing Concentricity:0.02mmRugosity:Ra0.8 Tolerance:0.01-0.022mm Diameter:Ø230mmFlatness:0.03mm L*W*H(mm)=230mm*230mm*50mm

Machine type:3Aixs CNC multiple Machining

Metal:Al(6061/7075),SUS(17-4PH/316/304),CU(Tungsten copper ).Machine:CNC 4 axis processing center,Wire cutting macine,CNC Mill.Surface treatment:Sand blast, Anodic oxidation, Plating.Purpose:automobile parts, Automotive parts,precision auto parts,

automotive hardware parts,motor car parts, antuo spare parts

Main Products Display

|

Processing all kinds of metal and plastic matenrials with the change of the times,the materials chosen by customers are changing constantly,in order to meet the different material needs of customers,we have accumulated a very rich and wide range of process characteristics and technical know-how of mechanical processing of metal and non-metal materials through continuous technological innovation and research and development. |

|||||

| Steel | Stainless steel | Aluminum | Copper | Plastic | Surface treatment |

| 1.2344 | SUS303 | A1050 | C1020 | PC | Sand blasting |

| SUJ2 | SUS304 | A2017 | C1100 | PP | Anodic oxidation |

| 1095 | SUS316 | A2024 | C145 | MC | Nickel plating |

| 1212 | SUS403 | A5056 | C147 | POM | Titanium plating |

| 1566 | SUS416 | A5052 | C5191 | ABS | Gold plating |

| S355 | SUS420J2 | A6020 | C1220 | PVC | Silver plating |

| C22 | SUS430 | A6061 | C360 | PEEK | Chrome Plated |

| C45 | SUS630 | A6063 | Others | PMMA | Blacking |

| F125 | 17-4PH | A6082 | Bakelite | flame plating | |

| F141 | Others | A7075 | Teflon | Abrasion | |

| CK45 | Others | Others | Chemical polishing | ||

| Others | Other | ||||

| Tolerance | Outer diameter dimension 0.01mmInternal diameter dimension 0.01mmCenter distance dimension 0.01mmlength,width,high0.01mmsurface roughness Ra0.4a Run-out 0.01mmRoundness 0.01mm Flatness 0.01mm | Customized drawings | AutoCAD,JPEG, PDF, STP, IGS, and most other file formats are accepted. |

| Application | Precision machinging, Unmanned aerial vehicle Motor & pump, Robotics, medical devices, Optical communication, Rotary Union, Automotive, 3D Face Recognition System, Tools and Fixtures, Gear & screw, hardware fasteners & Bolt &Shaft | Package | Paper cartons/plywood pallets/plywood boxes or according to customer's requirement |

KEY PRODUCTIONG EQUIPMENT DISPLAY

| Continuing to invest heavily in our facilities , we aim to bring you the most reliable,efficient and affordable metal component.our highly skilled and professional workforce is dedicated to satisfying the individual needs of all our customers and various markets the serve. | ||

| Processing type | surface treatment | Heat Treatment |

| CNC Machining | nickel plating | treatment |

| Multi-Axis CNC Machining | Gold plating | Passivation |

| CNC Turning Service | silver plating | Stress Removal Passivation |

| CNC Milling/Turning Multiple | chrome plating | Conditioning treatment |

| EDM | Titanium plating | quenching treatment |

| Thread Processing | Blackening treatment | Vacuum quenching treatment |

| wire cutting | anodizing | High cycle quenching |

| drilling | Sandblasting | Carburizing treatment |

| Gear working | Chemical grinding | salt-bath nitrocarburizing |

| stamping | dacromet | Tempering |

| laser cutting | zinc plating | Annealing treatment |

| Mechanical Parts Design | powder coated | |

| Parts Assemble | phosphatizing | |

Our advantages:

1. Precision Cnc stainless steel parts strictly according to customer's drawing,packing and quality request

2. Tolerance: Can be kept in +/-0.005mm

3. The most advanced CMM inspector to ensure the quality

4. Experienced technology engineers and well trained workers

5. Fast and timely delivery. Speedily&professional service

6. Give customer professional suggestion while in the process of customer designing to save costs.

Our freight price is often 30-50% lower than customer's

7. Customers can use PAYPAL and other online payment platform to pay a small amount of sample fee to

shorten the sample production time

8. Quality assurance in accordance with ISO9001:2015

FAQ:

Q1: Can XINYA make technical drawings for my design?

A1: We can provide a drawing for Manufacturing review according to your current

2D,3D CAD draft or a sample offered by you. We of course will sign and adhere

to any non-disclosure or confidentiality agreement if your design is confidential.

Q2: How long can I get a quotation?

A2: We respond within 24 hours when receive an RFQ. Normally a quotation will

take 1-3days. If there is delayed, we will notify you as soon as possible.

Q3: How quickly can I get my parts?

A3: Lead times is normally 2-3 weeks when get your complete 2D and 3D CAD

models from the order date. Complex parts requiring or large quality order will

take longer.We are able to be competent for some urgently needed project as well.

As for shipping, most of our shipments are via Express or by Air, which will take

3-7days to your door.

Q4: What after-sales service can I get for any unsatisfied parts I receive?

A4: To ensure high quality of our machined components, we have detailed quality

control system and full-equipped measuring equipments. We guarantee all the

dimension based on the information provided by you. We have confidence in

our ability to meet and exceed any reasonable expectations.