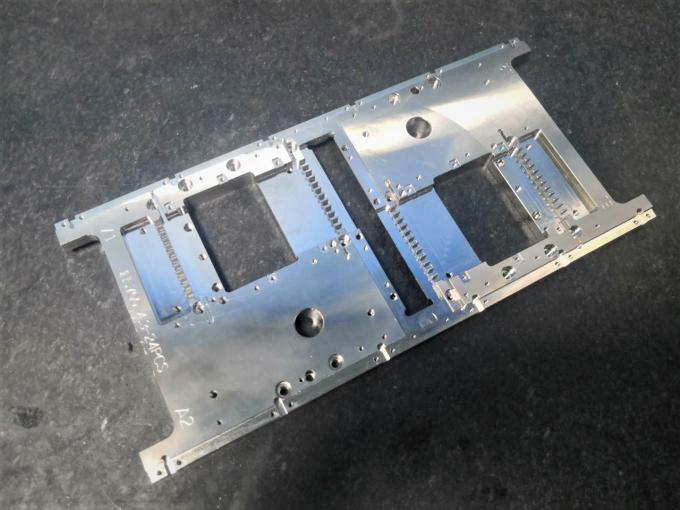

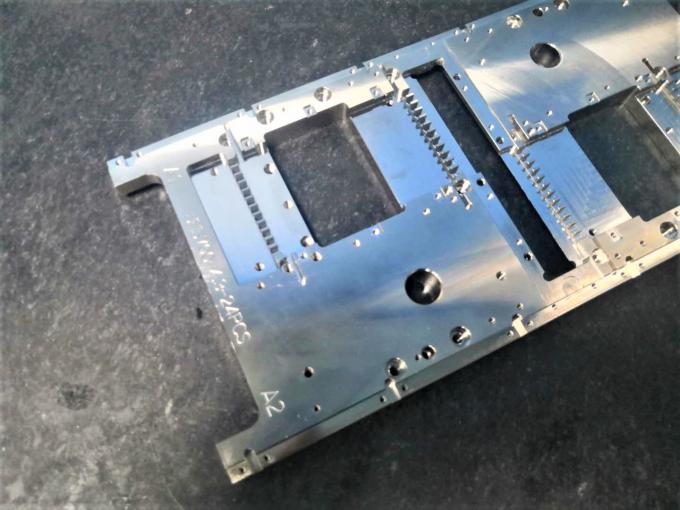

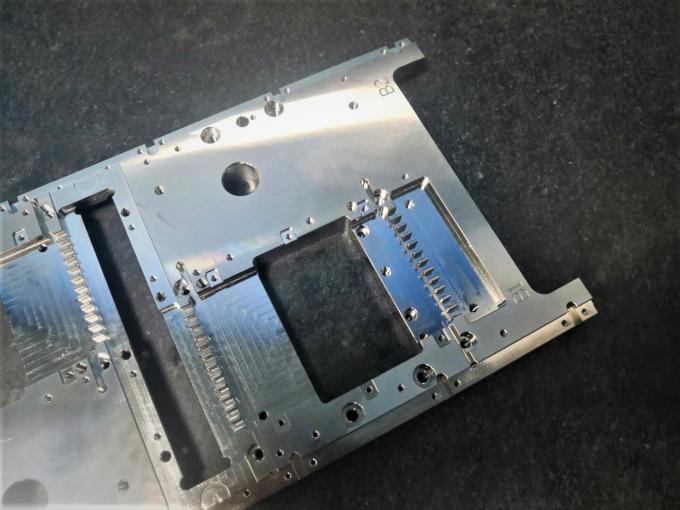

Aluminum Flatness 0.01mm Medical Machining Parts Nickel Plating

Aluminum Flatness 0.01mm Medical Machining Parts Nickel Plating Description

| Cnc Machining Or Not: | CNC Machining | Process: | Drilling/Bending/Stamping/Wire Cutting/Welding |

|---|---|---|---|

| Service: | OEM/ODM/Customized/Design | Material: | Aluminum |

| High Light: | Flatness 0.01mm Medical Machining Parts, Nickel Plating Medical Machining Parts, Ra0.6 Aluminum CNC Parts | ||

OEM High difficulty Flatness 0.01mm Medical Machining Parts Automatic Medicine

CT Componet Smooth Nickel plating

Product details:

CNC Medical Parts Machined Smooth Surface Treatment base of Medical instruments

automatic medicine CT componet parts

Material: AL7075 Surface:Nickel platingRugosity:Ra0.6

Tolerance:0.01-0.03mm Flatness:0.01mm Thickness=10.5mm

L*W*H(mm)=420mm*240mm*10.5mm

Main Product Display:

Metal:SUS(304/316/321/430/630/17-4PH/),AL(6061/7075),Cu(3604,1220),Steel

(1.2344,SUJ2,1095,1099,C45,Plastic(POM, PA, PVC, PEEK, PP)Machine:CNC processing center,CNC lathe,Wire cutting macine,Milling machine,Grinding machine,.Surface treatment:nickel plating,chrome plating,anodizing.Powder Coating

Purpose:Medical instruments,Computed Tomography(CT), endoscope, blood urine analyzer,

automatic production and packaging line of traditional Chinese medicine, automatic production

line of Western medicine.

Processing all kinds of metal and plastic matenrials with the change of the times,the materials

chosen by customers are changing constantly,in order to meet the different material needs

of customers,we have accumulated a very rich and wide range of process characteristics

and technical know-how of mechanical processing of metal and non-metal materials through

continuous technological innovation and research and development.

| Steel | Stainless steel | Aluminum | Copper | Plastic | Surface treatment |

| 1.2344 | SUS303 | A1050 | C1020 | PC | High speed sand blasting |

| SUJ2 | SUS304 | A2017 | C1100 | PP | Anodic oxidation |

| 1095 | SUS316 | A2024 | C145 | MC | Nickel plating |

| S355 | SUS420J2 | A6020 | C1220 | PVC | Silver plating |

| C22 | SUS430 | A6061 | C360 | PEEK | Chrome Plated |

| F125 | 17-4PH | A6082 | Bakelite | flame plating | |

| CK45 | Others | Others | Chemical polishing | ||

| Others | Others |

KeyMachine Display:

Continuing to invest heavily in our facilities , we aim to bring you the most reliable,efficient

and affordablemetal component.our highly skilled and professional workforce is dedicated

to satisfying the individualneeds of all our customers and various markets the serve.

Latest technology including:

CNC Milling Service

CNC Turning Service

CNC Milling and Turning Multiple

Mechanical Parts Design

Precision Engineering Services

EDM-Wire Cutting

Laser Cutting

Precision Grinding

Auto-Lathing Turning

MIM Moulding

Production Capabilities Minimum Tolerance

Outer diameter dimension(turning Process) 0.01mm

Outer diameter dimension(centerless grinding process) 0.005mm

Outer diameter dimension(step grinding process) 0.005mm

Internal diameter dimension(turning process) 0.01mm

Center distance dimension( CNC milling process) 0.01mm

length,width,high(cnc milling process) 0.01mm

surface roughness Ra0.2a

Run-out 0.01mm

Roundness 0.01mm

Flatness 0.01mm

perpendicular 0.01mm

Cylindricity 0.01mm

Why are you choose us ?

| Fully reinforced | 10 Years of Practical Experience | High Quality, Best Cost |

| Professional production equipment more than 60 sets, imported CNC, Japan's Jinshang turning and milling machine, all cutting processing completed at one time. Annual production of precision spare parts more than 10 million pieces, annual sales of more than 50 million RMB. | We have a professional and experienced team, with more than 10 years of mechanical processing experience. For nearly 1000 enterprises, factories customize hundreds of thousands of products. Focus on more professional, we intentionally do a good job in every product, in return for customer trust in us. | High precision, high speed, high-end equipment, In the long-term production process, we have established a perfect quality management system, so that the quality of products can be controlled steadily in the manufacturing process. To strive for the highest level of product quality beyond customer expectations. |

| Fastest response | Safe and Fast Logistics | Careful and meticulous service. |

| The fastest response, rapid delivery, strive for every minute and every second for customers. Quote quickly for 24 hours. Sample supply: Sample delivery period is 3-10 days. 365 days of production throughout the year. | All products are cleaned and rust-proof, and carefully packaged with cushioning materials and plastic suction boxes to ensure that nothing is wrong. Overseas logistics experience, FOB, CIF, DAP and other trade terms and air, sea, express and other logistics methods can be corresponding. | No matter the quantity of production, from trial production to batch production, we will take it seriously and do our best. Provide one-stop all-round service for mechanical processing, heat treatment, surface treatment and assembly. |

Quality policy

We understand that customer's satisfied with the quality and service is an important indicator

of successful companies.The way the company wins depends on high-precision machine for

high quality requirements of various components.We may not be able to get the lowest price,

but we will do our best to offer you the best quality products,we prefer to explain you about t

he price for a while,but don't want to apologize for the quality of life.If only pursuit of profit,

we can reduce costs to achieve the purpose of fast sales,but we believe that only the perfect

quality is what we prided,is our biggest value embodiment.Our efforts and perseverance have

also been recognized and followed by more and more customers.This is the biggest motivation

for us to continue and move forward.Good quality,the only way to express our thanks!

Our measuring equipment:

CMM

Projector

Concentricity measurement

Hardness tester

Thread Ring Gauges

Pin Gauges

Micrometer

Vernier Caliper

Roughness machine

Our precision machined components are implemented of ISO9001:2015,combined with our in-house

quality control system and these measuring equipments,ensure problem-free products.