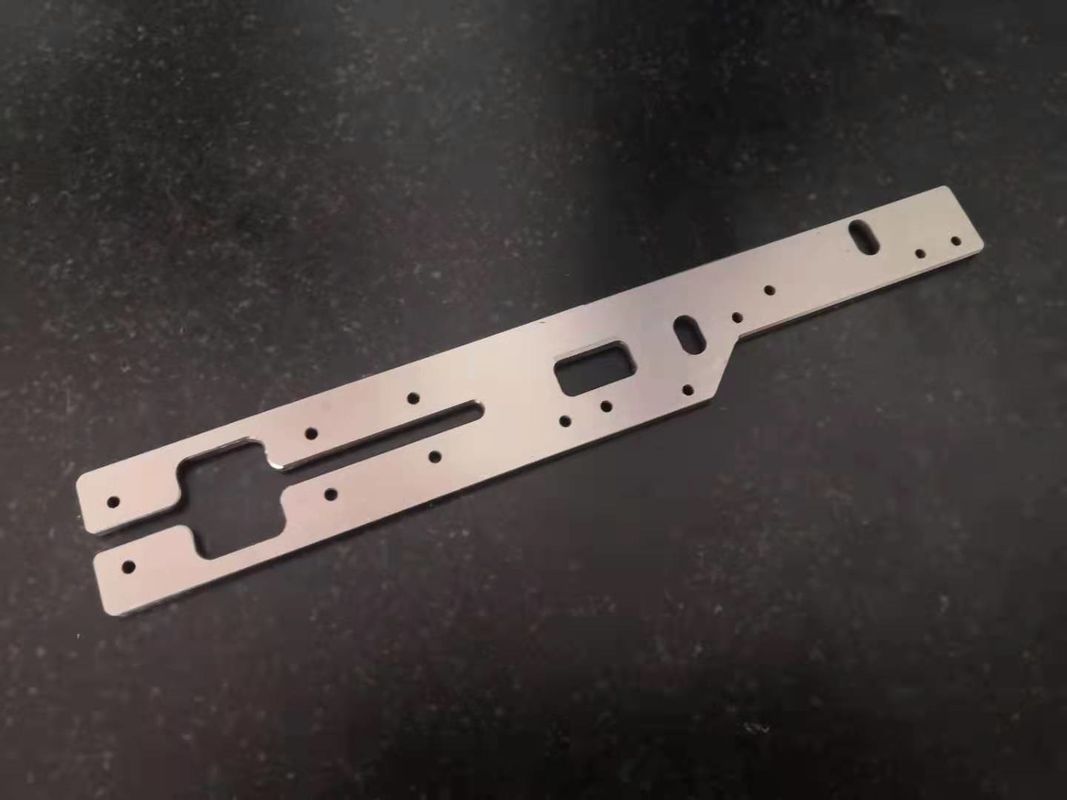

Anodizing Precision Machined Parts Cnc Milling Machine Parts Components

Anodizing Precision Machined Parts Cnc Milling Machine Parts Components Description

| Cnc Machining Or Not: | CNC Machining | Material Capabilities: | Stainless Steel,Brass,Steel Alloys,Copper |

|---|---|---|---|

| Service: | OEM/ODM/Customized/Design | Sample: | Available |

| Drawing Format: | IGES,PDF,STEP. STP,etc. | Size: | Customer’s Drawings |

| High Light: | cnc machined components, custom machined parts | ||

Anodizing Precision Machined Parts Cnc Milling Machine Parts Components

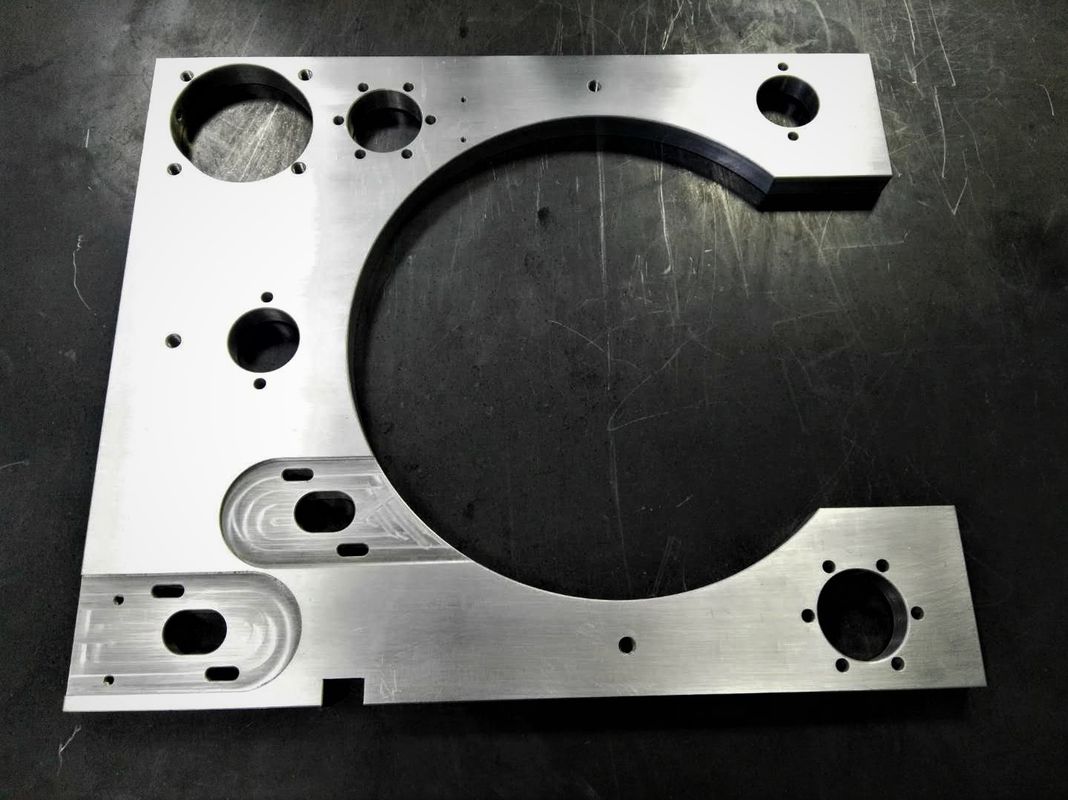

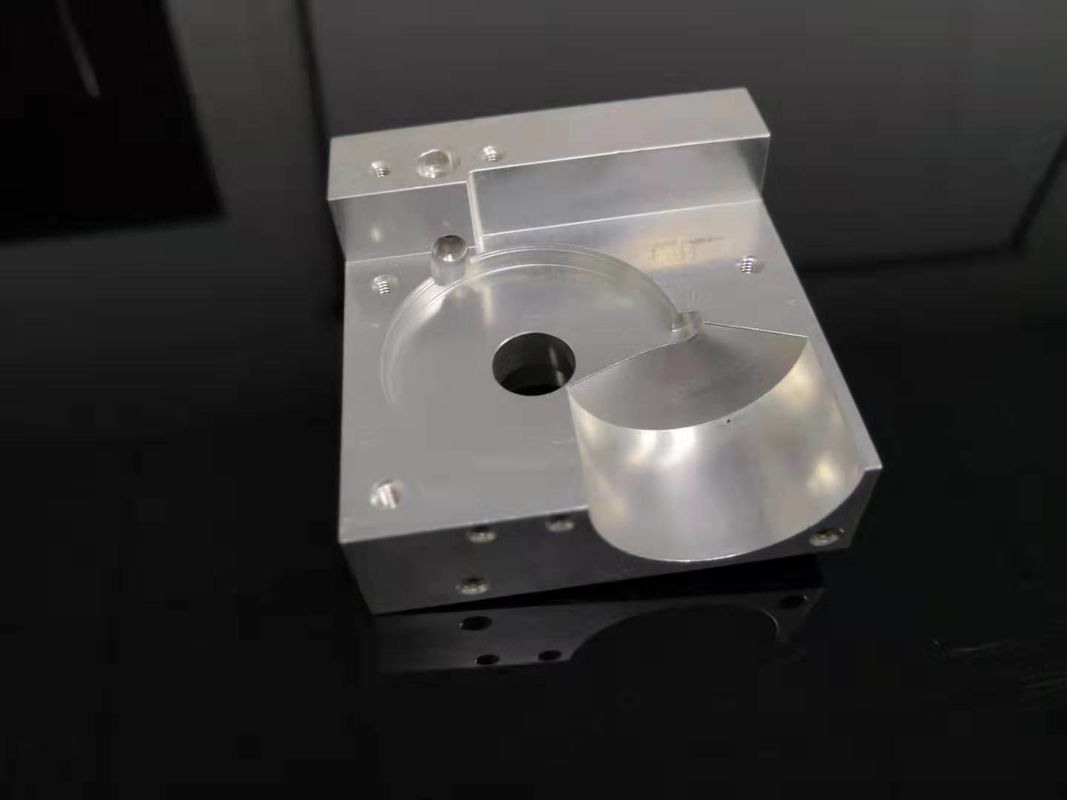

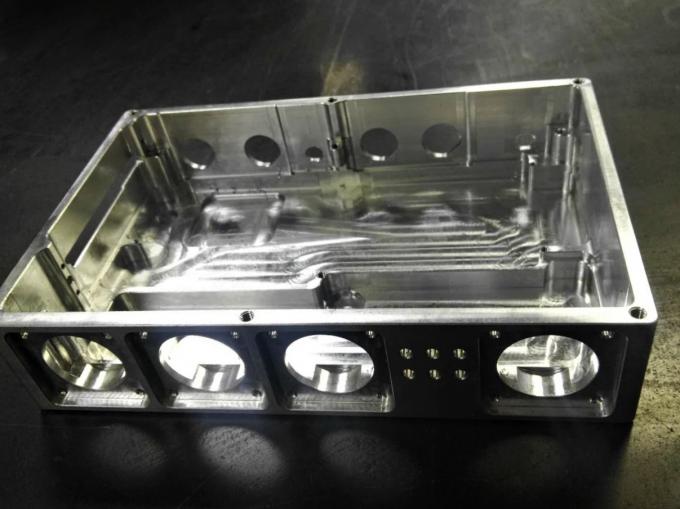

High Precision CNC Machining Optical communication Parts of Turning/Milling

optical communications frame parts Machined Parts

Material: Al6061 Surface:Anodizing Rugosity:Ra1.6

Tolerance:0.01-0.03mm Flatness:0.05mm L*W*H(mm)=150mm*100mm*50mm

Material:Fe-Ni-Co Alloy, SUS(316/304),Cooper(W-Cu/OFC/T2),etc.Machine equipments :CNC process center, CNC mill, CNC 5-axis lathe, Wire cutting(WEDM),etc.Surface treatment:Ni/Gold plating.Usage:Vessel, Military, Security system, Medical, Instrument measurement,Optical fiber transmission, etc.Optical Communication field

What can we do?

Latest technology including:

CNC Milling Service

CNC Turning Service

CNC Milling and Turning Multiple

Mechanical Parts Design

Precision Engineering Services

Parts Assemble

EDM-Wire Cutting

Laser Cutting

Precision Grinding

Auto-Lathing Turning

Injection Moulding

MIMMoulding Die Casting

Production Capabilities Minimum Tolerance

Outer diameter dimension(turning Process) 0.01mm

Outer diameter dimension(centerless grinding process) 0.005mm

Outer diameter dimension(step grinding process) 0.005mm

Internal diameter dimension(turning process) 0.01mm

Center distance dimension( CNC milling process) 0.01mm

length,width,high(cnc milling process) 0.01mm

surface roughness Ra0.2a

Run-out 0.01mm

Roundness 0.01mm

Flatness 0.01mm

perpendicular 0.01mm

Cylindricity 0.01mm

Why are you choose us ?

1) We have our own factories, quality can be controlled seriously.

2) We Specialize in manufacturing about10 years.

3) We have professional testing department and testing equipment.

4) We have 12 rich experience engineers & 20 senior technicians.

5) Timely delivery and excellent service.

6) We believe Reasonable price = High quality + Best service.

QC System:

1) Confirmed all drawings with customer and design the production way.

2) Checking the raw material before coming into our warehouse.

3) Confirmed the samples, reports of material and specs with customer.

4) Checking the process, machine, and other details in the production line.

5) Checking every products before packing them.

6) Checking the package before delivery.

We understand that customer's satisfied with the quality and service is an important

indicator of successful companies.The way the company wins depends on

high-precision machine for high quality requirements of various components.

We may not be able to get the lowest price,but we will do our best to offer you

the best quality products,we prefer to explain you about the price for a while,

but don't want to apologize for the quality of life.If only pursuit of profit,

we can reduce costs to achieve the purpose of fast sales,but we believe that

only the perfect quality is what we prided,is our biggest value embodiment.

Our efforts and perseverance have also been recognized and followed by more

and more customers.This is the biggest motivation for us to continue and move

forward.Good quality,the only way to express our thanks!

It is our goal to meet our customers’ expectation through good quality,

fast delivery service, productivity and continuous improvement.

Shenzhen Xinya Precsion Co., Ltd. and Hongkong Winhoo Precision Co.,Ltd

is to be your best choice and long-term partner.