Customized Aerospace Spare Parts Optical Base Defence Components Special Surface Treatment

Customized Aerospace Spare Parts Optical Base Defence Components Special Surface Treatment Description

| Cnc Machining Or Not: | CNC Machining | Material Capabilities: | Stainless Steel,Brass,Steel Alloys |

|---|---|---|---|

| Surface Treatment: | Painting/sand Blasting/oiled Etc. | Process: | Turning/Milling/Grinding |

| Service: | OEM/ODM Service | Equipment: | CNC Machining Centres |

| High Light: | aerospace spare parts, aerospace standard parts | ||

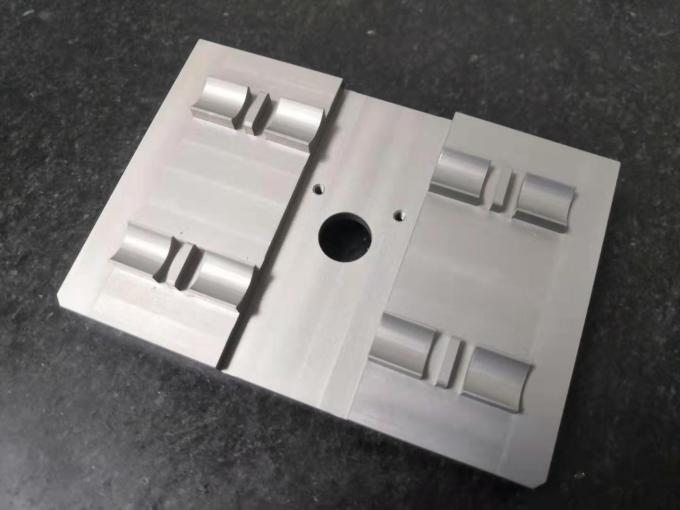

Customized Aerospace Spare Parts Optical base Defence Components Special surface treatment

Multi-Axis Machining OEM custom Aerospace Component Optical Bracket Aerospace and

Defence Parts Electric anodizedPrecision machined parts

Material: AL7075 Surface:Anodizing Concentricity:0.02mm

Rugosity:Ra0.8 Tolerance:0.01-0.02mm Flatness:0.01mm

L*W*H(mm)=85mm*68mm*25mm

Metal:Titanium TC4,TA9,AL2A12,AL6082,AL6061,AL7075,SUS304,30CrMn.Machine:CNC machinging center,CNC lathe,Wire cutting macine,Milling machine,Grinding machine,EDM.Surface treatment:sand blast,,anodizing,Engraving,Gold plating.Purpose:unmanned aerial vehicle,drone, UAV,Aerospace,Defense,Aircraft,Navigation, military.

Main Machining Machinery Display

| Continuing to invest heavily in our facilities , we aim to bring you the most reliable,efficient and affordable metal component.our highly skilled and professional workforce is dedicated to satisfying the individual needs of all our customers and various markets the serve. | ||

| Processing type | ||

| CNC Machining | EDM | Gear working |

| Multi-Axis CNC Machining | Thread Processing | stamping |

| CNC Turning Service | wire cutting | laser cutting |

| CNC Milling/Turning Multiple | drilling | Parts Assemble |

| Application | Precision machinging,Unmanned aerial vehicle & aerospace,Motor & pump,Robotics,medical devices,Optical communication,Rotary Union,Automotive,3D Face Recognition System,Tools and Fixtures,Gear & screw,hardware fasteners & Bolt & Shaft | Customized drawings | AutoCAD,JPEG,PDF,STP,IGS, and most other file formats are accepted. |

Why are you choose us ?

1) We have our own factories, quality can be controlled seriously.

2) We Specialize in manufacturing about10 years.

3) We have professional testing department and testing equipment.

4) We have 12 rich experience engineers & 20 senior technicians.

5) Timely delivery and excellent service.

6) We believe Reasonable price = High quality + Best service.

QC System:

1) Confirmed all drawings with customer and design the production way.

2) Checking the raw material before coming into our warehouse.

3) Confirmed the samples, reports of material and specs with customer.

4) Checking the process, machine, and other details in the production line.

5) Checking every products before packing them.

6) Checking the package before delivery.

FAQ:

Q1: Are you a manufacturer?

A1: Yes, we are a medium size ISO9001 certificated manufacturer with a wide range of advanced

equipment.Warmly welcome to visit our factory so that you can make sure this point.

Q2: What is the MOQ?

A2: Minimum Order Quantity is one piece/set.If you require more qty,the price can be more competitive.

Q3: Can you do the mass production?

A3: Yes,we are a factory which can provide service of precision CNC machining, rapid prototyping,

wire cutting, tooling building and etc.After you confirm the samples, we can start mass production.

It is very convienient for customers to

Choose us as a one-stop solution supplier.

Q4: Which 3D drawing files should go with the machines?

A4: CNC machines only read *IGS,*STP,*STEP,*IGES,*X-T format, for *STL format,it goes with 3D

printer and SLA.

Q5: Is it possible to know how are my products going on without visiting your company?

A5: We will offer a detailed production schedule and send weekly reports with pictures or videos

which show the machining progress.