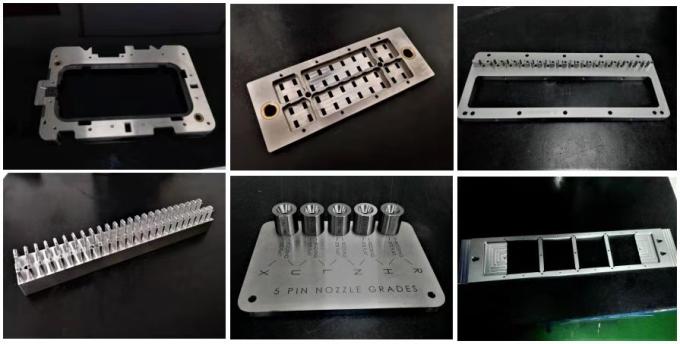

Customized Precision Fixtures CNC Medical Tools And Fixtures Machining

Customized Precision Fixtures CNC Medical Tools And Fixtures Machining Description

| Cnc Machining Or Not: | CNC Machining | Material: | Steel/stainless Steel/aluminum/brass |

|---|---|---|---|

| Surface Treatment: | Powder Coating/plating/anodized | Process: | Cnc Tuning,milling,cnc Machining |

| Application: | Medical,Auto Part/mechanical Parts/Electronic Parts | Product Name: | Customized OEM Custom Steel Cnc Precision Milling Jig Fixture |

| High Light: | cnc precision components, inspection fixture components | ||

Customized Precision Fixtures CNC Medical Tools And Fixtures Machining

Customized Precision CNC Medical Tools and Fixtures Machining Smooth Surface Treatment

Material: SUS304 Surface:chemical polishing Rugosity:Ra0.4

Tolerance:0.01-0.03mm Flatness:0.05mm L*W*H(mm)=250mm*80mm*40mm

Metal:1.2344,SUJ2,45#,F125,F141,CK45,SLD,S136,Q235

SUS304,POM,PVC,steel,Al,section bar, electrical device,etc..machine:CNC processing center,CNC lathe,Wire cutting macine,Milling machine,

Grinding machine,EDM,wire cutting, Grinder, Bench, Metal plate.Surface treatment:Ni plating, Anodizing,etc.Purpose:Industrial using(Customization).Mobile phone assembly fixture,

Steaming fixture with optical lenses, Inspection fixture of Optical Communication Products,

Diamond Grinding fixture,Ceramic Products fixture,Electrical conduction inspection fixture,

Medical Wire Harness fixture,Auto parts assembly fixture,

Main Products Display

| Processing all kinds of metal and plastic matenrials with the change of the times,the materials chosen by customers are changing constantly,in order to meet the different material needs of customers,we have accumulated a very rich and wide range of process characteristics and technical know-how of mechanical processing of metal and non-metal materials through continuous technological innovation and research and development. | |||||

| Steel | Stainless steel | Aluminum | Copper | Plastic | Surface treatment |

| 1.2344 | SUS303 | A1050 | C1020 | PC | High speed sand blasting |

| SUJ2 | SUS304 | A2017 | C1100 | PP | Anodic oxidation |

| 1095 | SUS316 | A2024 | C145 | MC | Nickel plating |

| 1212 | SUS403 | A5056 | C147 | POM | Titanium plating |

| 1566 | SUS416 | A5052 | C5191 | ABS | Gold plating |

| S355 | SUS420J2 | A6020 | C1220 | PVC | Silver plating |

| C22 | SUS430 | A6061 | C360 | PEEK | Chrome Plated |

| C45 | SUS630 | A6063 | Others | PMMA | Blacking |

| F125 | 17-4PH | A6082 | Bakelite | flame plating | |

| F141 | A7075 | Teflon | Abrasion | ||

| CK45 | Others | Others | Chemical polishing | ||

| Others | Others | ||||

Main Machining Machinery Display

| Continuing to invest heavily in our facilities , we aim to bring you the most reliable,efficient and affordable metal component.our highly skilled and professional workforce is dedicated to satisfying the individual needs of all our customers and various markets the serve. | ||

| Processing type | surface treatment | Heat Treatment |

| CNC Machining | nickel plating | treatment |

| Multi-Axis CNC Machining | Gold plating | Passivation |

| CNC Turning Service | silver plating | Stress Removal Passivation |

| CNC Milling/Turning Multiple | chrome plating | Conditioning treatment |

| EDM | Titanium plating | quenching treatment |

| Thread Processing | Blackening treatment | Vacuum quenching treatment |

| wire cutting | anodizing | High cycle quenching |

| drilling | Sandblasting | Carburizing treatment |

| Gear working | Chemical grinding | salt-bath nitrocarburizing |

| stamping | dacromet | Tempering |

| laser cutting | zinc plating | Annealing treatment |

| Mechanical Parts Design | powder coated | |

| Parts Assemble | phosphatizing | |

Quality policy

To focus on "customer satisfaction" as the premise condition of core business tenet, company personnel

to promote lean production management mode. With the evolution and development of precision metal

parts manufacturing industry chain, we recognized that the industrial chain of enterprise survival based

on quality and product services to guests. To this end, we continue to introduce foreign high-precision

processing and testing equipment; product process simple optimizing continuously; constantly improve

product quality standards and other aspects of enterprise management innovation, the company has won

high praise and affirmation from customers.

Marketr and Service

We Are Committed To Fulfilling Your Needs,We Are Proud Of Your Every Success

Why are you choose us ?

1. Rich CNC machining experience.

XINYA was founded in 2008years, having a long history of 10 years.

Full experience accumulated in Precision CNC machining service on best quality

for medical, communications, photoelectric, auto parts processing,CNC Precision

machining. Mechanical processing – heat treatment – surface treatment and

assembly, we are committed to offer you and one-stop solution .

2. We have do business with many foreign customers from Europe/North America/

Aisa etc areas, like we have cooperation with GE and SUMITOMO,CANON for

around 10years. No matter how much the production is, we will take it seriously

and do our best.

3. We have had 60 sets machining,including CNC automatic lathes imported from

Japan, So this will help our company have bigger manufacturing capacity.

To meet more customers' precision request, we have CMM, PROJECTOR etc.

Precision inspection instruments to measuring our products.

In order to ensure quality, we carry out strict first sample inspection, process

inspection, shipment inspection, and every process is strictly checked. We try

every means to prevent defective products from flowing into the next

process and customer place.

4. We offer OEM/ODM service with reasonable production techniques for

customers to cut down the cost. Our engineering team use the UG/PROE/

SOLIDWORKS/MASTER etc software to support our production techniques.

5. Overseas logistics experience, FOB, CIF, DAP and other trade terms.

It is our goal to meet our customers’ expectation through good quality,

fast delivery service, productivity and Continuous improvement.

Shenzhen Xinya Precsion machining Co., Ltd is to be your best choice

and long-term partner.

FAQ:

Q1: Can XINYA make technical drawings for my design?

A1: We can provide a drawing for Manufacturing review according to your current 2D,3D CAD draft

or a sample offered by you. We of course will sign and adhere to any non-disclosure or confidentiality

agreement if your design is confidential.

Q2: How long can I get a quotation?

A2: We respond within 24 hours when receive an RFQ. Normally a quotation will take 1-3days.

If there is delayed, we will notify you as soon as possible.

Q3: How quickly can I get my parts?

A3: Lead times is normally 2-3 weeks when get your complete 2D and 3D CAD models from the

order date. Complex parts requiring or large quality order will take longer.We are able to be

competent for some urgently needed project as well.As for shipping, most of our shipments are

via Express or by Air, which will take 3-7days to your door.

Q4: What after-sales service can I get for any unsatisfied parts I receive?

A4: To ensure high quality of our machined components, we have detailed quality control system