High Precision Custom Cnc Lathe Machine Parts Turning Milling Metal Brass Aluminum

High Precision Custom Cnc Lathe Machine Parts Turning Milling Metal Brass Aluminum Description

| Cnc Machining Or Not: | CNC Machining | Process: | Drilling/Bending/Stamping/Wire Cutting/Punching/Grinding/Welding |

|---|---|---|---|

| Service: | OEM/ODM/Customized/Design | Sample: | Available |

| Drawing Format: | IGES,PDF,STEP. STP,DWG,X-T | Material: | Brass,copper,Aluminum,Stainless Steel,etc |

| High Light: | cnc turned components, precision turned parts | ||

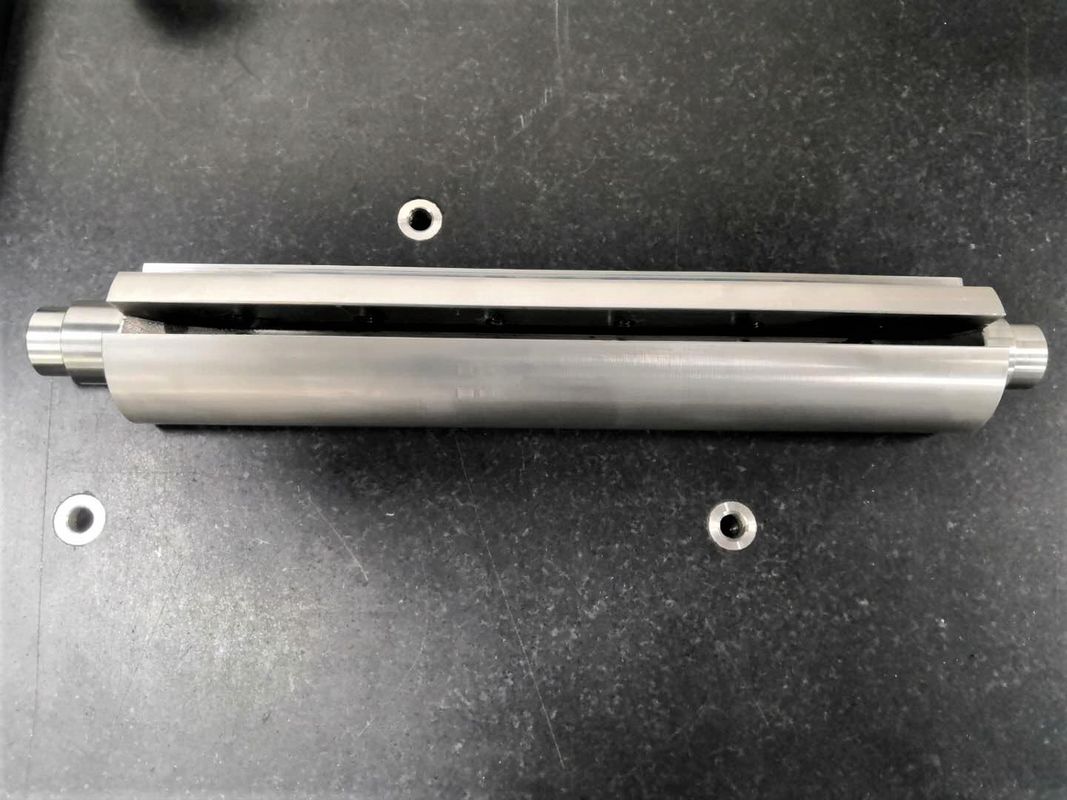

High Precision Custom Cnc Lathe Machining Turning Milling Metal Stainless Steel Copper Brass Aluminum

Product details:

High Precision Spare Machine Partsspiral patternCover Shell of Electronic Products

Colour anodizing Appearance Parts Communication Equipment parts

Material: C3604 Rugosity:Ra0.8 Tolerance:0.02-0.05mm

L*W*H(mm)=15mm*15mm*28mm,

Main Product Display:

Metal:Aluminum2024,2A12,5052,6020,6061,6063,7075,45#,SKD11,DC53,SUS304,SUS136.Machine:CNC lathe,Centering Machine,Multi-Axis turning,Surface treatment:nickel plating,chrome plating,anodizing.Purpose:Semiconductor Machinery,Laser Cutting Equipment,Communication equipment,

Medical equipment,agricultural machinery,electrical appliances products,Generator parts,

Bathroom Parts,Ship accessories,Electric Tool Parts,Monitoring equipment,Communication

Equipment,Audio Equipment Parts,Digital Camera Parts,Mining Machinery Parts,

Petroleum Mining Machinery Parts,Juice extractor parts,Mountaineering Equipment Parts,

Fishing gear parts,Sports Equipment Parts,Fitness Equipment Parts,Photographic

equipment parts,Furniture Hardware Parts,Mower Parts

Processing all kinds of metal and plastic matenrials with the change of the times,the materials

chosen by customers are changing constantly,in order to meet the different material needs

of customers,we have accumulated a very rich and wide range of process characteristics

and technical know-how of mechanical processing of metal and non-metal materials through

continuous technological innovation and research and development.

KeyMachine Display:

Continuing to invest heavily in our facilities , we aim to bring you the most reliable,efficient

and affordablemetal component.our highly skilled and professional workforce is dedicated

to satisfying the individualneeds of all our customers and various markets the serve.

| Processing type | ||

| CNC Machining | EDM | Gear working |

| Multi-Axis CNC Machining | Thread Processing | stamping |

| CNC Turning Service | wire cutting | laser cutting |

| CNC Milling/Turning Multiple | drilling | Parts Assemble |

Production Capabilities Minimum Tolerance

Outer diameter dimension(turning Process) 0.01mm

Outer diameter dimension(centerless grinding process) 0.005mm

Outer diameter dimension(step grinding process) 0.005mm

Internal diameter dimension(turning process) 0.01mm

Center distance dimension( CNC milling process) 0.01mm

length,width,high(cnc milling process) 0.01mm

surface roughness Ra0.2a

Run-out 0.01mm

Roundness 0.01mm

Flatness 0.01mm

perpendicular 0.01mm

Cylindricity 0.01mm

Why are you choose us ?

1.Advanced facilities ensure the Top quality ,

over 80 sets high precision CNC machines

2. Same/Better quality with Germany ,USA

3. 20 sets 3,4,5 axis CNC from Japan and taiwan.

4. Certificate: ISO9001

5. 100% guarantee quality , lead time .

6. Reports available for PPAP,CPK,PFMEA,CONTROL PLAN etc

What is CNC?

The Basics Of CNC Machining

CNC (Computer Numerical Controlled) machining is a means to remove material with high precision machines,

using a wide variety of cutting tools to create the final design. Common CNC machines include vertical milling

machines, horizontal milling machines, lathes, and routers.

How CNC Machining Works

To successfully make a part on a CNC machine, skilled machinists create programmed instructions using CAM

(Computer Aided Manufacturing) software in conjunction with the CAD (Computer Aided Design) model

provided by the customer. The CAD model is loaded into the CAM software and tool paths are created based

on the required geometry of the manufactured part. Once the tool paths are determined, the CAM software

creates G-Code (machine code) that tells the machine how fast to move, how fast to turn the stock and/or tool,

and where to move the tool or workpiece in a 5-axis X, Y, Z, A, and B coordinate system.