Industrial CNC Hardware Parts Centering Machine Processing Parts Mobile Nut Screw

Industrial CNC Hardware Parts Centering Machine Processing Parts Mobile Nut Screw Description

| Type: | Turning | Material Capabilities: | Aluminum,Stainless Steel,Brass,Steel Alloys,Copper |

|---|---|---|---|

| Service: | Customized OEM,Customized OEM CNC Turning Machining | Drawing Format: | PDF,AI,.pdf / .dwg / .igs / .stp / X_t.,JPEG,PSD |

| Metal: | C22,C45,F141,1.2344,SUS303,SUS304 | Surface Polishing: | Zinc Plating,brass Plating |

| High Light: | precision hardware parts, cnc turned components | ||

Industrial CNC Hardware Parts Centering Machine Processing Parts Mobile Nut Screw

Product details:

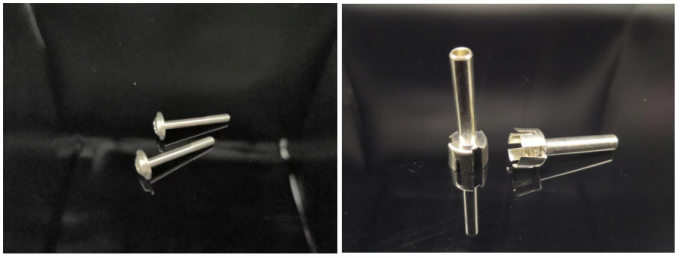

Customized Steel CNC Turning Parts Centering Machine Processing Parts Mobile Nut Screw

general hardware fasteners industrial

Material: C22 Surface:dacromet Concentricity:0.05mm

Rugosity:Ra0.8 Tolerance:0.03-0.05mm Diameter:Ø6mm

L*W*H(mm)=6mm*6mm*20mm

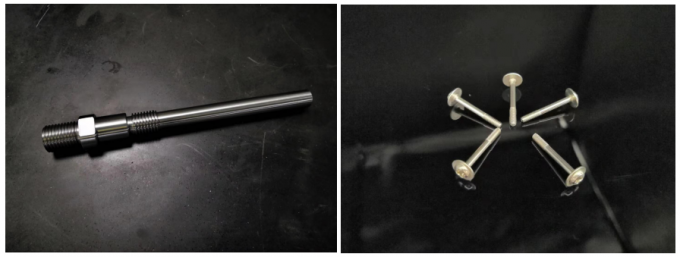

Main Products Display:

Metal:C22,C45,F141,1.2344,SUS303,SUS304,SUS316,30CrMn, Black Oxide Stainless Steel,

Solid Brass, and Silicon Bronze,Plastic.Machine:Multi-Axis turning,CNC lathe,CNC machinging center,.Surface polishing,zinc plating,brass plating,nickel plating,dacromet,electrophoresis,Passivation,etc.

Heat Treatment.Purpose:All kinds of machinery,Equipment,Vehicles,Ships,Railway,Bridges,Architecture,Structure,

Tools,Instruments,Electronic products,Medical instruments,optical instrument

| Processing all kinds of metal and plastic matenrials with the change of the times,the materials chosen by customers are changing constantly,in order to meet the different material needs of customers,we have accumulated a very rich and wide range of process characteristics and technical know-how of mechanical processing of metal and non-metal materials through continuous technological innovation and research and development. | |||||

| Steel | Stainless steel | Aluminum | Copper | Plastic | Surface treatment |

| 1.2344 | SUS303 | A1050 | C1020 | PC | High speed sand blasting |

| SUJ2 | SUS304 | A2017 | C1100 | PP | Anodic oxidation |

| 1095 | SUS316 | A2024 | C145 | MC | Nickel plating |

| 1212 | SUS403 | A5056 | C147 | POM | Titanium plating |

| 1566 | SUS416 | A5052 | C5191 | ABS | Gold plating |

| S355 | SUS420J2 | A6020 | C1220 | PVC | Silver plating |

| C22 | SUS430 | A6061 | C360 | PEEK | Chrome Plated |

| C45 | SUS630 | A6063 | Others | PMMA | Blacking |

| F125 | 17-4PH | A6082 | Bakelite | flame plating | |

| F141 | A7075 | Teflon | Abrasion | ||

| CK45 | Others | Others | Chemical polishing | ||

| Others | Others | ||||

KeyEquipmentDisplay

| Continuing to invest heavily in our facilities , we aim to bring you the most reliable,efficient and affordable metal component.our highly skilled and professional workforce is dedicated to satisfying the individual needs of all our customers and various markets the serve. | ||

| Processing type | surface treatment | Heat Treatment |

| CNC Machining | nickel plating | treatment |

| Multi-Axis CNC Machining | Gold plating | Passivation |

| CNC Turning Service | silver plating | Stress Removal Passivation |

| CNC Milling/Turning Multiple | chrome plating | Conditioning treatment |

| EDM | Titanium plating | quenching treatment |

| Thread Processing | Blackening treatment | Vacuum quenching treatment |

| wire cutting | anodizing | High cycle quenching |

| drilling | Sandblasting | Carburizing treatment |

| Gear working | Chemical grinding | salt-bath nitrocarburizing |

| stamping | dacromet | Tempering |

| laser cutting | zinc plating | Annealing treatment |

| Mechanical Parts Design | powder coated | |

| Parts Assemble | phosphatizing | |

Quality Management System

Customer's requirement is our standard. In the long-term production process, we have

established a perfect quality management system, so that product quality can be controlled

steadily in the manufacturing process. We strictly enforce the operation rules and quality

standards from the aspects of material purchasing, R&D and design, process flow and

quality inspection, all of which originate from our unremitting pursuit of quality.

We can't give you the lowest price, we can only give you good quality. We would rather

explain the price to you for a while than apologize for the quality for a lifetime. If we only

want to pursue profits, we can achieve the goal of fast sales by reducing costs. But we think

that only perfect quality is our pride, in order to promise that we will not be proud of

short-term benefits. Selling the future, our efforts and persistence are recognized and

followed by more and more customers, which is the greatest driving force for us to continue

to move forward. We can not thank you, but only report quality.

| Quality Inspection Links and Inspection Items | Introduction of Various Quality Testing Instruments | ||

| 1.Inspection of raw materials | 3CMM | ||

| IQC Inspectors will inspect surface,size and matcertificate provided of materials. |  |

CMM can be defined as "a detector which can move in three directions. |  |