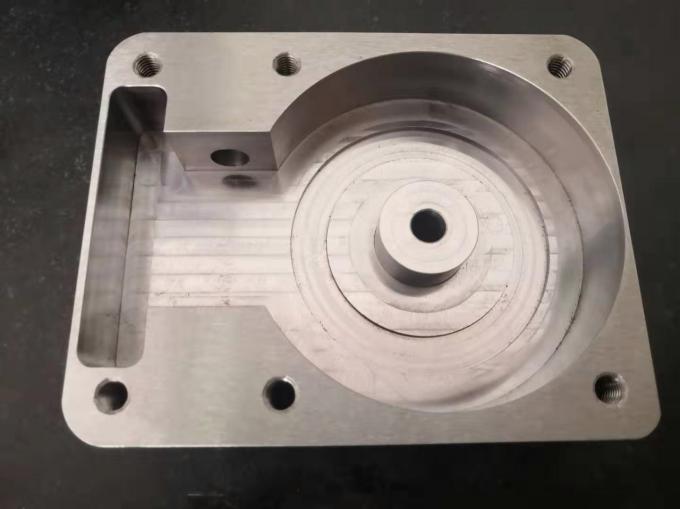

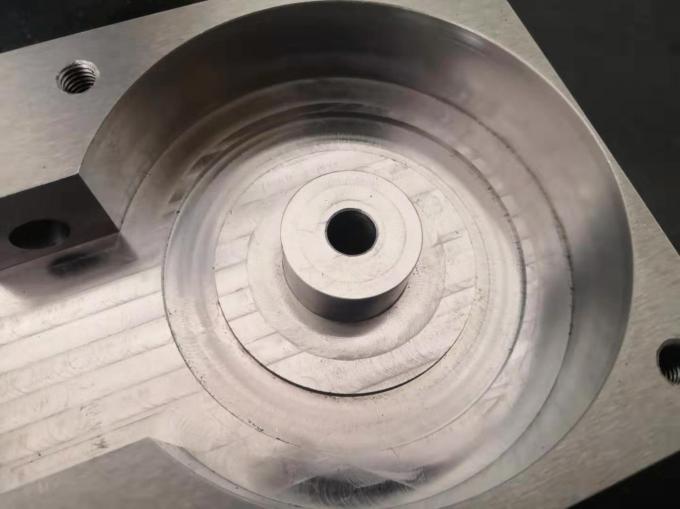

Petroleum Metal Machined Parts Case Generator Spare Parts Chrome Plating

Petroleum Metal Machined Parts Case Generator Spare Parts Chrome Plating Description

| Cnc Machining Or Not: | CNC Machining | Process: | Drilling/Bending/Stamping/Wire Cutting/Punching/Grinding/Welding |

|---|---|---|---|

| Service: | OEM/ODM/Customized/Design | Sample: | Available |

| Drawing Format: | IGES,PDF,STEP. STP, | Material: | Brass,copper,Aluminum,etc |

| High Light: | cnc milling service, metal machining services | ||

Petroleum Metal Machined Parts Case Generator Spare Parts Chrome Plating

Product details:

High Precision CNC Machining Steel Parts Machined Aluminum Components case

Generator parts Ship accessories Petroleum Machinery Parts

Material: 45# Surface:chrome plating Concentricity:0.03mm

Rugosity:Ra0.8 Tolerance:0.01-0.03mm Flatness:0.05mm

L*W*H(mm)=250mm*150mm*88mm

Main Product Display:

Metal:2024,2A12,5052,6020,6061,6063,7075,45#,SKD11,DC53,SUS304,SUS136.SKD11,DC53.

Plastic(POM, PEEK, PP)

Machine:CNC processing center,Wire cutting macine,Milling machine,Grinding machine,EDM.Surface treatment:nickel plating,chrome plating,anodizing.

Purpose:Communication equipment,Testing equipment,Electronics equipment,agricultural

machinery,electrical appliances products,Generator parts,Bathroom Parts,Ship accessories,

Electric Tool Parts,Monitoring equipment,Communication Equipment,Audio Equipment Parts,

Digital Camera Parts,Mining Machinery Parts,Petroleum Mining Machinery Parts,Bridge

structural parts,Microscope Bracket Parts,Juice extractor parts,Mountaineering Equipment Parts,

Fishing gear parts,Sports Equipment Parts,Fitness Equipment Parts,Photographic equipment parts,

Processing all kinds of metal and plastic matenrials with the change of the times,the materials

chosen by customers are changing constantly,in order to meet the different material needs

of customers,we have accumulated a very rich and wide range of process characteristics

and technical know-how of mechanical processing of metal and non-metal materials through

continuous technological innovation and research and development.

KeyMachine Display:

Continuing to invest heavily in our facilities , we aim to bring you the most reliable,efficient

and affordablemetal component.our highly skilled and professional workforce is dedicated

to satisfying the individualneeds of all our customers and various markets the serve.

| Processing type | ||

| CNC Machining | EDM | Gear working |

| Multi-Axis CNC Machining | Thread Processing | stamping |

| CNC Turning Service | wire cutting | laser cutting |

| CNC Milling/Turning Multiple | drilling | Parts Assemble |

Production Capabilities Minimum Tolerance

Outer diameter dimension(turning Process) 0.01mm

Outer diameter dimension(centerless grinding process) 0.005mm

Outer diameter dimension(step grinding process) 0.005mm

Internal diameter dimension(turning process) 0.01mm

Center distance dimension( CNC milling process) 0.01mm

surface roughness Ra0.2a

Run-out 0.01mm

Roundness 0.01mm

perpendicular 0.01mm

Cylindricity 0.01mm

Why are you choose us ?

1) We have our own factories, quality can be controlled seriously.

2) We Specialize in manufacturing about10 years.

3) We have professional testing department and testing equipment.

4) We have 12 rich experience engineers & 20 senior technicians.

5)We believe Reasonable price = High quality + Best service.

QC System:

1) Confirmed all drawings with customer and design the production way.

2) Checking the raw material before coming into our warehouse.

3) Confirmed the samples, reports of material and specs with customer.

FAQ:

Q1: What do you need to make a quotation?

A1: To make a good quotation should be sure by the following things:

1. Existing samples or products drawings or 3D model data files.

2. Your request for products you are going to make, including quantity, material, finish.

Q2: How much time do you need to quote?

A2: Usually a quotation for a product is sent in 24 hours after we receive enquiry with all the

necessary details

Q3: How long does it take to have products?

A3: It varies a little depending on product size and complexity of its shape and the quantity.

We will give our exact delivery time when you get the quotation.

Q4: What guarantee that you will make them as good as we do?

A4: We can offer 1~3 pcs of samples to you for approval, if the quality is OK, and we will

proceed our business. We always inspect all specification shown on drawings, and we can

offer Inspect Report to you.

Q5: If you make parts and there are wrong do you refund out money?

A5: If the parts are wrong, we will return your money or we can make correct parts to you again.

Quality policy

Quality manufacturing we strive for perfection,we maintain good technical

interaction with suppliers and customers with efforts to drive for quality excellence in our products,

we take pride in every of our manufacturing and management process to eliminate errors and

deficiencies .

We understand that customer's satisfied with the quality and service is an important indicator of

successful companies.The way the company wins depends on high-precision machine for high

quality requirements of various components.

CMM

Projector

Hardness tester

Thread Ring Gauges

Pin Gauges

Micrometer

Vernier Caliper

Roughness machine