POM CNC Medical Parts 3D Printed Plastic Structural Roller Shaft Gear

POM CNC Medical Parts 3D Printed Plastic Structural Roller Shaft Gear Description

| Cnc Machining Or Not: | CNC Machining | Process: | Drilling/Stamping/Wire Cutting/Punching/Grinding/Welding |

|---|---|---|---|

| Service: | OEM/Customized/Design | Sample: | Available |

| Drawing Format: | IGES,PDF,STEP. STP,DWG,X-T | Material: | Brass,copper,Aluminum,Stainless Steel,etc |

| High Light: | medical spare parts, medical machining parts | ||

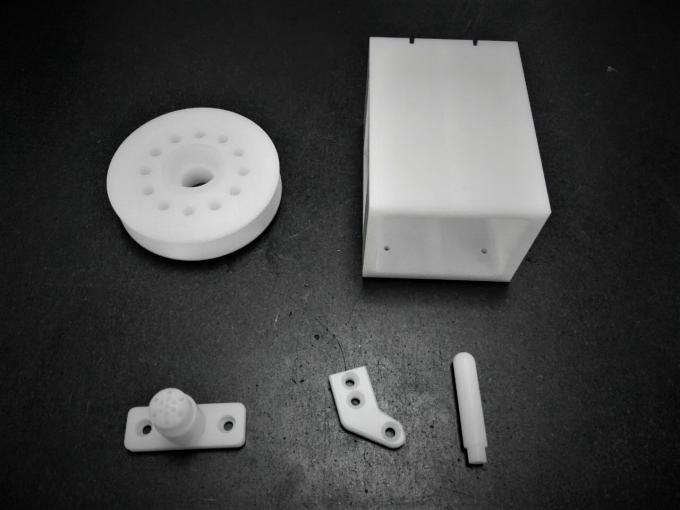

POM CNC Medical Parts 3D Printed Plastic Structural Roller Shaft Gear

Product details:

CNC Medical High-performanceCNC Endoscope Parts POM Custom Machined Parts

3D printed medical devices parts Plastic structural Roller Shaft Gear

Material: POM Concentricity:0.05mm Rugosity:Ra0.8

Diameter:Ø85mmTolerance:0.01-0.05mm L*W*H(mm)=85mm*85mm*22mm

Main Product Display:

Metal:SUS(304/316/321/430/630/17-4PH/),AL(6061/7075),Cu(3604,1220),Steel (1.2344,SUJ2,1095,1099,C45,F125,F141,ck45,Plastic(POM, PA, PVC, PEEK, PP)Machine:CNC processing center,CNC lathe,Wire cutting macine,Milling machine,Grinding machine,.Surface treatment:nickel plating,chrome plating,anodizing.Powder Coating

Purpose:Medical instruments,Computed Tomography(CT),Dightal Radiology(DR) ,

Magnetic resonance imaging (MRI), hematology analyzer, protein analyzer, needle Injection molding

jig and fixture, automatic production and packaging lineof traditional Chinese medicine, automatic

production line of Western medicine.

Processing all kinds of metal and plastic matenrials with the change of the times,the materials

chosen by customers are changing constantly,in order to meet the different material needs

of customers,we have accumulated a very rich and wide range of process characteristics

and technical know-how of mechanical processing of metal and non-metal materials through

continuous technological innovation and research and development.

| Steel | Stainless steel | Aluminum | Copper | Plastic | Surface treatment |

| 1.2344 | SUS303 | A1050 | C1020 | PC | High speed sand blasting |

| SUJ2 | SUS304 | A2017 | C1100 | PP | Anodic oxidation |

| 1095 | SUS316 | A2024 | C145 | MC | Nickel plating |

| 1212 | SUS403 | A5056 | C147 | POM | Titanium plating |

| 1566 | SUS416 | A5052 | C5191 | ABS | Gold plating |

| S355 | SUS420J2 | A6020 | C1220 | PVC | Silver plating |

| C22 | SUS430 | A6061 | C360 | PEEK | Chrome Plated |

| C45 | SUS630 | A6063 | Others | PMMA | Blacking |

| F125 | 17-4PH | A6082 | Bakelite | flame plating | |

| F141 | A7075 | Teflon | Abrasion | ||

| CK45 | Others | Others | Chemical polishing | ||

| Others | Others |

KeyMachine Display:

| Continuing to invest heavily in our facilities , we aim to bring you the most reliable,efficient and affordable metal component.our highly skilled and professional workforce is dedicated to satisfying the individual needs of all our customers and various markets the serve. | ||

| Processing type | ||

| CNC Machining | EDM | Gear working |

| Multi-Axis CNC Machining | Thread Processing | stamping |

| CNC Turning Service | wire cutting | laser cutting |

| CNC Milling/Turning Multiple | drilling | Parts Assemble |

Production Capabilities Minimum Tolerance

Outer diameter dimension(turning Process) 0.01mm

Outer diameter dimension(centerless grinding process) 0.005mm

Outer diameter dimension(step grinding process) 0.005mm

Internal diameter dimension(turning process) 0.01mm

Center distance dimension( CNC milling process) 0.01mm

length,width,high(cnc milling process) 0.01mm

surface roughness Ra0.2a

Run-out 0.01mm

Roundness 0.01mm

Flatness 0.01mm

perpendicular 0.01mm

FAQ:

Q: What do I need for offering a quote ?A: Please offer us 2D or 3D drawings (with material, dimension, tolerance, surface treatment

and other technical requirement etc.) ,quantity, application or samples.

Then we will quote the best price within24h.Q: What is your MOQ?A: MOQ depends on our client's needs for cnc machining parts, besides,we welcome trial order

before mass-production.Q: What is the production cycle?A: It varies a lot depending on product dimension,technical requirements and quantity.

We always try to meet customers' requirement by adjusting our workshop schedule.Q: What kind of payment terms do you accept?A: T/T, Alipay, paypal, western union, moneygram etc.Q: Is it possible to know how is my product going on without visiting your company?A: We will offer a detailed products schedule and send weekly reports with digital pictures and

videos which show the machining progress.Q: If you make poor quality goods,will you refund our payment?A: We make products according to drawings or samples strictly until them reach your 100%

satisfaction.And actually we wont take a chance to do poor quality products.We are proud of

keeping the spirit of good quality.

Quality policy

Corporate mission:

We provide a full range of solutions in precision processing parts for manufacturing industry.

We provide high quality product and sharing the beauty life with the world top processing

machine and profession

Corporate desire:

Become the pioneer of precision metal parts industry chain.to create to global competitive

enterprise with extraordinary wisdom and creativity,with great power and energy,the

greatest benefit is created,and the expectation of society is rewarded to the maximum.

Our measuring equipment:

CMM

Projector

Hardness tester

Thread Ring Gauges

Pin Gauges

Micrometer

Roughness machine

Our precision machined components are implemented of ISO9001:2015,combined with our in-house

quality control system and these measuring equipments,ensure problem-free products.

Marketr and Service We Are Committed To Fulfilling Your Needs,We Are Proud Of Your Every Success