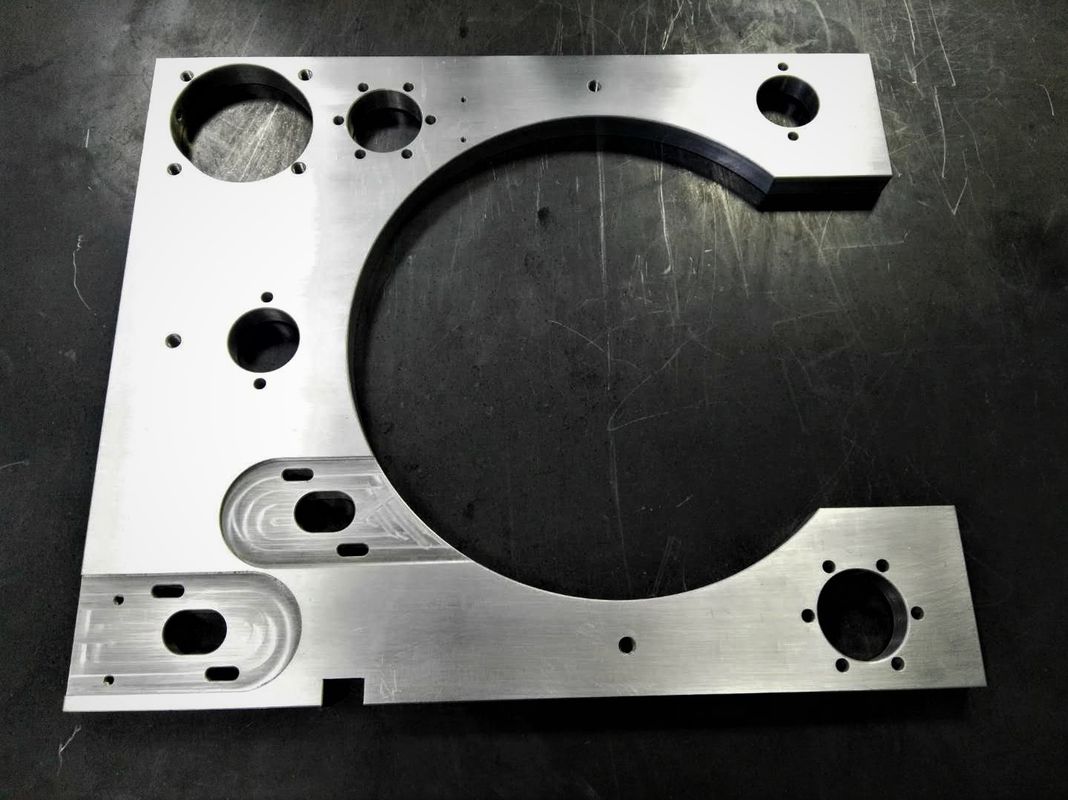

S45C Prototype Machining Services Medical Equipment Parts 20mm Thickness

S45C Prototype Machining Services Medical Equipment Parts 20mm Thickness Description

| Cnc Machining Or Not: | CNC Machining | Process: | Drilling/Bending/Stamping/Wire Cutting/Punching/Grinding/Welding |

|---|---|---|---|

| Service: | OEM/ODM/Customized/Design | Sample: | Available |

| Drawing Format: | IGES,PDF,STEP. STP,DWG,X-T | Material: | Brass,copper,Aluminum,Stainless Steel,etc |

| High Light: | cnc machined components, precision cnc machining parts | ||

S45C Prototype Machining Services Medical Equipment Parts 20mm Thickness

Product details:

Customized CNC machiningBase of automatic production machine lineMedical equipment parts

Electronics equipment parts Fitness Equipment Parts Large-size plate

Material: 45# S45C Surface:Hardchrome plating Rugosity:Ra0.4

Tolerance:0.01-0.05mmFlatness:0.05mm Thickness=20mm

Verticality:0.03mm Heat Treatment=HRC45 L*W*H(mm)=800mm*700mm*20mm,

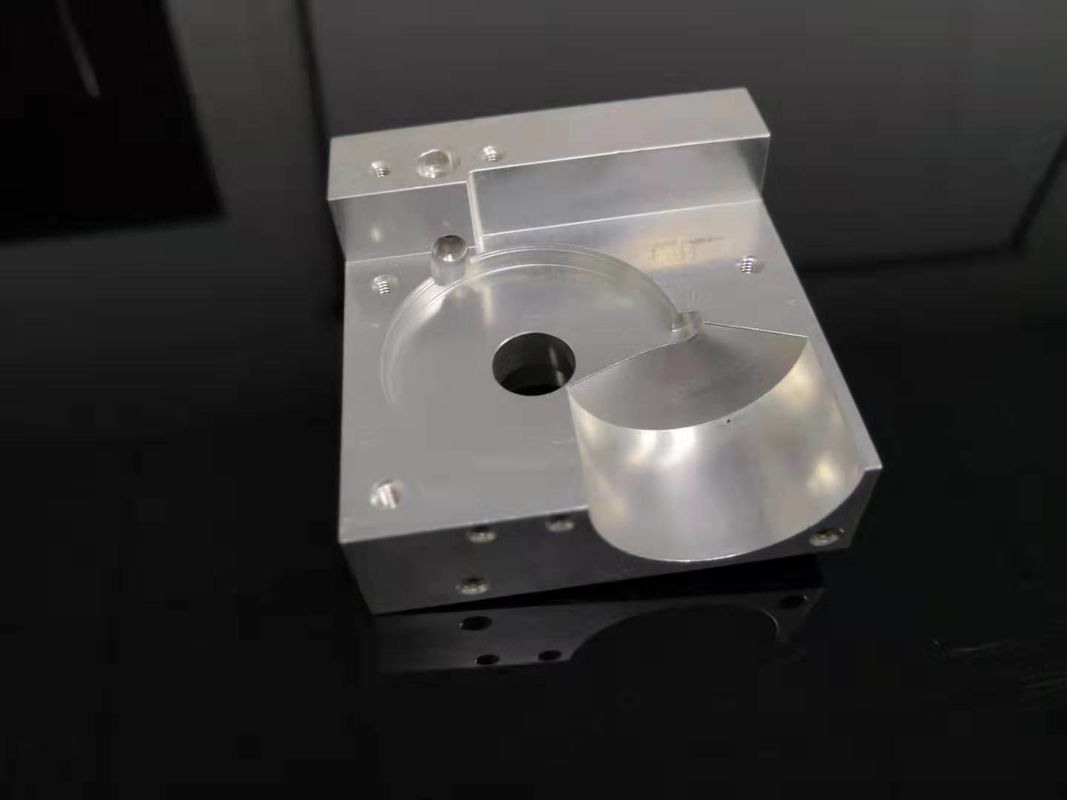

Main Product Display:

Metal:Aluminum 2024,2A12,5052,6020,6061,6063,7075,45#,SKD11,DC53,SUS304,SUS136.Machine:CNC processing center,CNC lathe,Wire cutting macine,Milling machine,Grinding machine,EDM.Surface treatment:nickel plating,chrome plating,anodizing.

Purpose:Semiconductor Machinery,Laser Cutting Equipment,Communication equipment,

Testing equipment,Medical equipment,Electronics equipment,agricultural machinery,

electrical appliances products,Electronic devices, SMT Industrial field, etc.Vessel, Military,

Security system, Medical, Instrument measurement,Optical fiber transmission, etc.Optical

Bridge structural parts,Microscope Bracket Parts,Juice extractor parts,Mountaineering

Equipment Parts,Fishing gear parts,Sports Equipment Parts,Fitness Equipment Parts,

Photographic equipment parts,Furniture Hardware Parts,Mower Parts,

Processing all kinds of metal and plastic matenrials with the change of the times,the materials

chosen by customers are changing constantly,in order to meet the different material needs

of customers,we have accumulated a very rich and wide range of process characteristics

and technical know-how of mechanical processing of metal and non-metal materials through

continuous technological innovation and research and development.

| Steel | Stainless steel | Aluminum | Copper | Plastic | Surface treatment |

| 1.2344 | SUS303 | A1050 | C1020 | PC | High speed sand blasting |

| SUJ2 | SUS304 | A2017 | C1100 | PP | Anodic oxidation |

| 1095 | SUS316 | A2024 | C145 | MC | Nickel plating |

| 1212 | SUS403 | A5056 | C147 | POM | Titanium plating |

| 1566 | SUS416 | A5052 | C5191 | ABS | Gold plating |

| S355 | SUS420J2 | A6020 | C1220 | PVC | Silver plating |

| C22 | SUS430 | A6061 | C360 | PEEK | Chrome Plated |

| C45 | SUS630 | A6063 | Others | PMMA | Blacking |

| F125 | 17-4PH | A6082 | Bakelite | flame plating | |

| F141 | A7075 | Teflon | Abrasion | ||

| CK45 | Others | Others | Chemical polishing | ||

| Others | Others |

| Heat Treatment | ||

| treatment | Conditioning treatment | High cycle quenching |

| Passivation | quenching treatment | Carburizing treatment |

| Stress Removal Passivation | Vacuum quenching treatment | salt-bath nitrocarburizing |

| Annealing treatment | Tempering | |

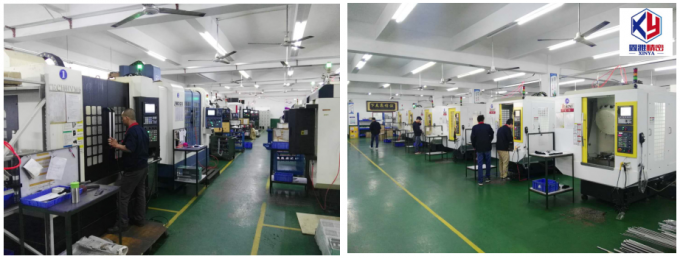

keyMachine Display:

Continuing to invest heavily in our facilities , we aim to bring you the most reliable,efficient

and affordablemetal component.our highly skilled and professional workforce is dedicated

to satisfying the individualneeds of all our customers and various markets the serve.

Latest technology including:

CNC Milling Service

CNC Turning Service

CNC Milling and Turning Multiple

Mechanical Parts Design

Precision Engineering Services

Parts Assemble

EDM-Wire Cutting

Laser Cutting

Precision Grinding

Auto-Lathing Turning

Injection Moulding

MIMMoulding Die Casting

Production Capabilities Minimum Tolerance

Outer diameter dimension(turning Process) 0.01mm

Outer diameter dimension(centerless grinding process) 0.005mm

Outer diameter dimension(step grinding process) 0.005mm

Internal diameter dimension(turning process) 0.01mm

Center distance dimension( CNC milling process) 0.01mm

length,width,high(cnc milling process) 0.01mm

surface roughness Ra0.2a

Run-out 0.01mm

Roundness 0.01mm

Flatness 0.01mm

perpendicular 0.01mm

Cylindricity 0.01mm

Why are you choose us ?

| Fully reinforced | 10 Years of Practical Experience | High Quality, Best Cost |

| Professional production equipment more than 60 sets, imported CNC, Japan's Jinshang turning and milling machine, all cutting processing completed at one time. Annual production of precision spare parts more than 10 million pieces, annual sales of more than 50 million RMB. | We have a professional and experienced team, with more than 10 years of mechanical processing experience. For nearly 1000 enterprises, factories customize hundreds of thousands of products. Focus on more professional, we intentionally do a good job in every product, in return for customer trust in us. | High precision, high speed, high-end equipment, In the long-term production process, we have established a perfect quality management system, so that the quality of products can be controlled steadily in the manufacturing process. To strive for the highest level of product quality beyond customer expectations. |

| Fastest response | Safe and Fast Logistics | Careful and meticulous service. |

| The fastest response, rapid delivery, strive for every minute and every second for customers. Quote quickly for 24 hours. Sample supply: Sample delivery period is 3-10 days. 365 days of production throughout the year. | All products are cleaned and rust-proof, and carefully packaged with cushioning materials and plastic suction boxes to ensure that nothing is wrong. Overseas logistics experience, FOB, CIF, DAP and other trade terms and air, sea, express and other logistics methods can be corresponding. | No matter the quantity of production, from trial production to batch production, we will take it seriously and do our best. Provide one-stop all-round service for mechanical processing, heat treatment, surface treatment and assembly. |

FAQ:

Q: What do I need for offering a quote ?A: Please offer us 2D or 3D drawings (with material, dimension, tolerance, surface treatment and

other technical requirement etc.) ,quantity, application or samples.

Then we will quote the best price within24h.Q: What is your MOQ?A: MOQ depends on our client's needs for cnc machining parts, besides,we welcome trial order

before mass-production.Q: What is the production cycle?A: It varies a lot depending on product dimension,technical requirements and quantity.

We always try to meet customers' requirement by adjusting our workshop schedule.Q: What kind of payment terms do you accept?A: T/T, Alipay, paypal, western union, moneygram etc.Q: Is it possible to know how is my product going on without visiting your company?A: We will offer a detailed products schedule and send weekly reports with digital pictures

and videos which show the machining progress.Q: If you make poor quality goods,will you refund our payment?A: We make products according to drawings or samples strictly until them reach your

100% satisfaction.And actually we wont take a chance to do poor quality products.

We are proud of keeping the spirit of good quality.

Marketr and Service We Are Committed To Fulfilling Your Needs,We Are Proud Of Your Every Success