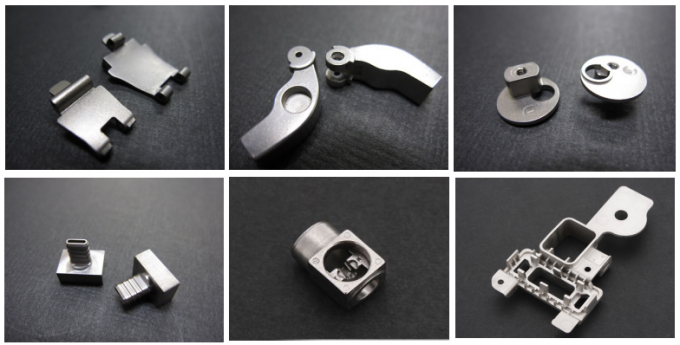

Stainless Steel 316 Metal Injection Molding Parts , Eletronic Mim Parts

Stainless Steel 316 Metal Injection Molding Parts , Eletronic Mim Parts Description

| Material: | Stainless Steel | Surface Treatment: | Powder Coating |

|---|---|---|---|

| Application: | Medical Equipment/Electronic Parts/Industry/Furniture Etc | Product Name: | Stainless Steel 316/304 |

| Service: | OEM/ODM | Tolerance: | 0.05mm~0.10mm |

| Standard: | ASTM & AISI & DIN | ||

| High Light: | mim parts, mim components | ||

Stainless Steel 316 Metal Injection Molding Parts , Eletronic Mim Parts

Product Details:

Metal Injection Molding parts Customized Eletronic Component Powder Metallurgy

Sintering Parts Precision Mim ofSolenoid Valves Gears Bearings Surgical

Material: SUS316 Tolerance:0.01-0.05mm Diameter:Ø12mm

L*W*H(mm)=12mm*12mm*20mm,

Main product display:

Metal:SUS316,SUS630,SUS410,SUS304,SUS420,SUS440

Machine:Injection molding machine,Sintering furnace

Suface treatment:Sintering

Purpose:Micro-Motor,Sheatsinke,Sensors,Solenoid Valves,Gears,Bearings,

Small Pump.Smicro-Actuators,Connectors,Medical Parts,Dental Equipment,

Equipment Inspection,Surgical,Bicycle Parts,Fishing Equipment,Golf Equipment,

Musical Instruments.

Metal injection molding, or MIM, is a manufacturing process in which metal powder is

mixed and kneaded together with a binder material and wax. The mixture is then

injected into a mold to form a compact. The molded compact is debound and sintered

to obtain the metal components.A wide variety of materials is available. Materials with

high melting points or poor machinability are usable.A smooth surface can be obtained

using a powder containing fine particles.It is possible to combine and assemble two or

more partsAny net shape is available, without any restrictions on side holes or under-cuts.Excellent transcription of fine letters or patterns.Thin-walled structures are available.

Complex three-dimensional metal components can be mass-produced with high accuracy.

The process may be used to convert production from machining or investment casting.

High geometric accuracy and consistant quality among individual products.Relative

density above 95% enables good mechanical properties.Surface treatment such as

plating is available, as for conventional metal products.

Our Quality Policy

Quality manufacturing we strive for perfection,we maintain good technical

interaction with suppliers and customers with efforts to drive for quality excellence

in our products,we take pride in every of our manufacturing and management process

to eliminate errors and deficiencies .

We understand that customer's satisfied with the quality and service is an important

indicator of successful companies.The way the company wins depends on high-precision

machine for high quality requirements of various components.

We may not be able to get the lowest price,but we will do our best to offer you the best

quality products,we prefer to explain you about the price for a while,but don't want to

apologize for the quality of life.If only pursuit of profit,we can reduce costs to achieve

the purpose of fast sales,but we believe that only the perfect quality is what we prided,

is our biggest value embodiment.Our efforts and perseverance have also been recognized

and followed by more and more customers.This is the biggest motivation for us to continue

and move forward.Good quality,the only way to express our thanks!

Xinya precision — professional Precision metal parts industry for more than ten years

Continuously provide for you quality and speed try our best do everything.

Main Products Display

|

Processing all kinds of metal and plastic matenrials with the change of the times,the materials chosen by customers are changing constantly,in order to meet the different material needs of customers,we have accumulated a very rich and wide range of process characteristics and technical know-how of mechanical processing of metal and non-metal materials through continuous technological innovation and research and development. |

|||||

| Steel | Stainless steel | Aluminum | Copper | Plastic | Surface treatment |

| 1.2344 | SUS303 | A1050 | C1020 | PC | High speed sand blasting |

| SUJ2 | SUS304 | A2017 | C1100 | PP | Anodic oxidation |

| 1095 | SUS316 | A2024 | C145 | MC | Nickel plating |

| 1212 | SUS403 | A5056 | C147 | POM | Titanium plating |

| 1566 | SUS416 | A5052 | C5191 | ABS | Gold plating |

| S355 | SUS420J2 | A6020 | C1220 | PVC | Silver plating |

| C22 | SUS430 | A6061 | C360 | PEEK | Chrome Plated |

| C45 | SUS630 | A6063 | Others | PMMA | Blacking |

| F125 | 17-4PH | A6082 | Bakelite | flame plating | |

| F141 | Others | A7075 | Teflon | Abrasion | |

| CK45 | Others | Others | Chemical polishing | ||

| Others | Othe | ||||

KEY PRODUCTIONG EQUIPMENT DISPLAY

| Continuing to invest heavily in our facilities , we aim to bring you the most reliable,efficient and affordable metal component.our highly skilled and professional workforce is dedicated to satisfying the individual needs of all our customers and various markets the serve. | ||

| Processing type | surface treatment | Heat Treatment |

| CNC Machining | nickel plating | treatment |

| Multi-Axis CNC Machining | Gold plating | Passivation |

| CNC Turning Service | silver plating | Stress Removal Passivation |

| CNC Milling/Turning Multiple | chrome plating | Conditioning treatment |

| EDM | Titanium plating | quenching treatment |

| Thread Processing | Blackening treatment | Vacuum quenching treatment |

| wire cutting | anodizing | High cycle quenching |

| drilling | Sandblasting | Carburizing treatment |

| Gear working | Chemical grinding | salt-bath nitrocarburizing |

| stamping | dacromet | Tempering |

| laser cutting | zinc plating | Annealing treatment |

| Mechanical Parts Design | powder coated | |

| Parts Assemble | phosphatizing | |

why are you choose us ?