Steel Alloys Precision Turned Parts For Optical Communications Frame

Steel Alloys Precision Turned Parts For Optical Communications Frame Description

| Cnc Machining Or Not: | CNC Machining | Material Capabilities: | Aluminum,Stainless Steel,Brass,Steel Alloys,Copper |

|---|---|---|---|

| Service: | OEM/ODM/Customized/Design | Sample: | Available |

| Drawing Format: | IGES,PDF,STEP. STP,DWG,X-T | Size: | Customer’s Drawings |

| High Light: | cnc machined components, custom machined parts | ||

Steel Alloys Precision Turned Parts For Optical Communications Frame

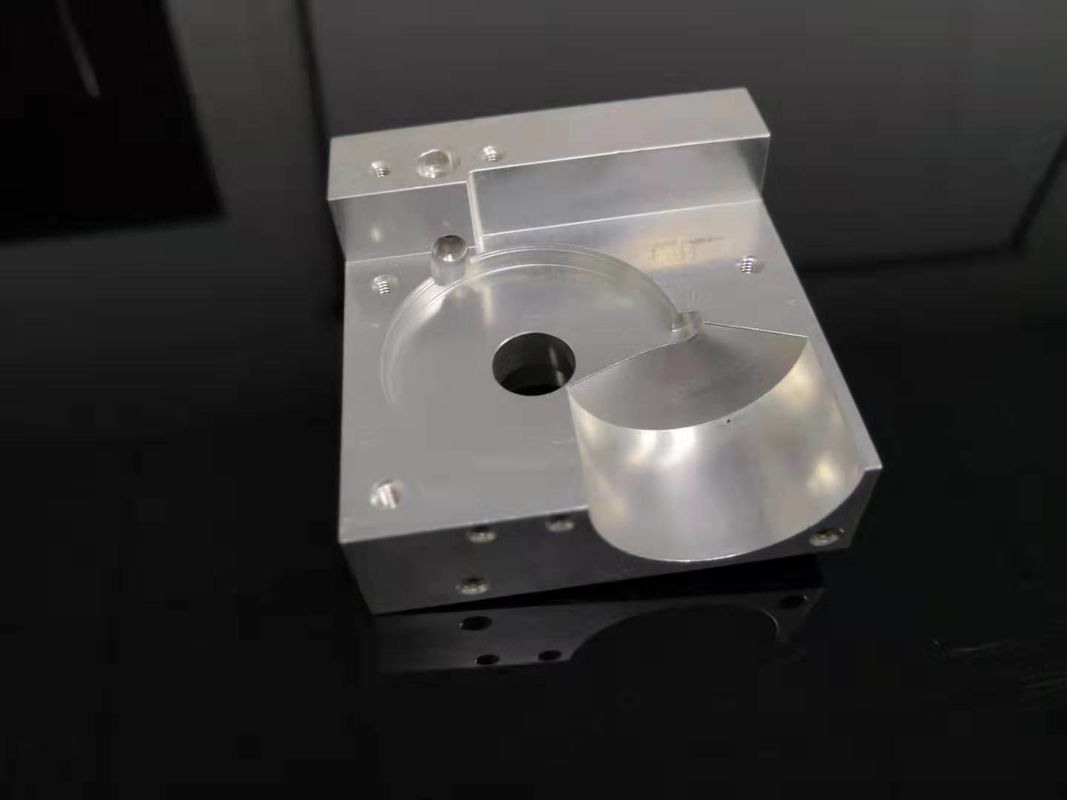

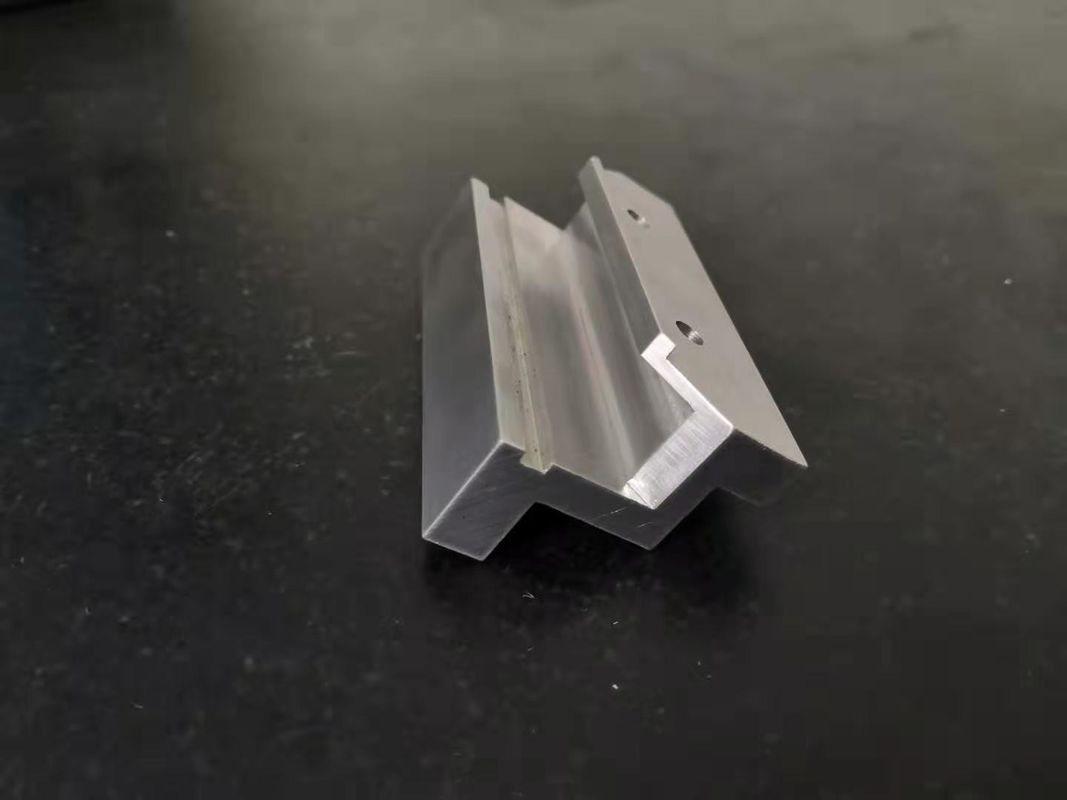

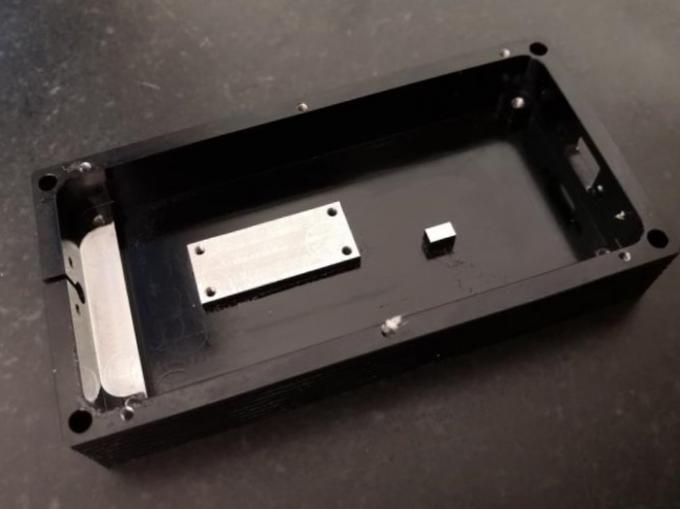

High Precision CNC Machining Optical communication Parts of Turning/Milling

optical communications frame parts Machined Parts

Material: Al6061 Surface:Anodizing Rugosity:Ra1.6

Tolerance:0.01-0.03mm Flatness:0.05mm L*W*H(mm)=150mm*100mm*50mm

Material:Fe-Ni-Co Alloy, SUS(316/304),Cooper(W-Cu/OFC/T2),etc.Machine equipments :CNC process center, CNC mill, CNC 5-axis lathe, Wire cutting(WEDM),etc.Surface treatment:Ni/Gold plating.Usage:Vessel, Military, Security system, Medical, Instrument measurement,Optical fiber transmission, etc.Optical Communication field

Processing all kinds of metal and plastic matenrials with the change of the times,the

materials chosen by customers are changing constantly,in order to meet the different

material needs of customers,we have accumulated a very rich and wide range of process

characteristics and technical know-how of mechanical processing of metal and non-metal

materials through continuous technological innovation and research and development.

| Steel | Stainless steel | Aluminum | Copper | Plastic | Surface treatment |

| 1.2344 | SUS303 | A1050 | C1020 | PC | High speed sand blasting |

| SUJ2 | SUS304 | A2017 | C1100 | PP | Anodic oxidation |

| 1095 | SUS316 | A2024 | C145 | MC | Nickel plating |

| 1212 | SUS403 | A5056 | C147 | POM | Titanium plating |

| 1566 | SUS416 | A5052 | C5191 | ABS | Gold plating |

| S355 | SUS420J2 | A6020 | C1220 | PVC | Silver plating |

| C22 | SUS430 | A6061 | C360 | PEEK | Chrome Plated |

| C45 | SUS630 | A6063 | Others | PMMA | Blacking |

| F125 | 17-4PH | A6082 | Bakelite | flame plating | |

| F141 | A7075 | Teflon | Abrasion | ||

| CK45 | Others | Others | Chemical polishing | ||

| Others | Others |

Continuing to invest heavily in our facilities , we aim to bring you the most reliable,efficient

and affordable metal component.our highly skilled and professional workforce is dedicated

to satisfying the individual needs of all our customers and various markets the serve.

Latest technology including:

CNC Milling Service

CNC Turning Service

CNC Milling and Turning Multiple

Mechanical Parts Design

Precision Engineering Services

Parts Assemble

EDM-Wire Cutting

Laser Cutting

Precision Grinding

Auto-Lathing Turning

Injection Moulding

MIMMoulding Die Casting

Production Capabilities Minimum Tolerance

Outer diameter dimension(turning Process) 0.01mm

Outer diameter dimension(centerless grinding process) 0.005mm

Outer diameter dimension(step grinding process) 0.005mm

Internal diameter dimension(turning process) 0.01mm

Center distance dimension( CNC milling process) 0.01mm

length,width,high(cnc milling process) 0.01mm

surface roughness Ra0.2a

Run-out 0.01mm

Roundness 0.01mm

Flatness 0.01mm

perpendicular 0.01mm

Cylindricity 0.01mm

FAQ:

Q1: Could you give me your best price?

A1: Of course yes, we are a professional manufacturer, so we could supply the best price

without many middlemen.

Q2: If my quantity is very small, could you do my products?

A2: Yes, we can. Do not worry about the quantity. We will provide different production ways

based on your quantity.

Q3: How can you guarantee the quality?

A3: We have a powerful QC team to control the quality in every production process.

We believe the best quality is our enterprise life. That’s why we have lots of big group companies.

Q4: I want to buy your products, how can I make the payment?

A4: We can accept the T/T and western union.

Q5: What are your mainly customers around the world?

A5: Our mainly customers are from North American, Western Europe and Japan.

If you have any further questions, please just feel free to contact me directly. I will try my best to

service you and your company. I hope we will be a good cooperation in the futuue

Corporate mission:

We provide a full range of solutions in precision processing parts for manufacturing industry.

We provide high quality product and sharing the beauty life with the world top processing

machine and profession

Corporate desire:

Become the pioneer of precision metal parts industry chain.to create to global competitive

enterprise with extraordinary wisdom and creativity,with great power and energy,the greatest

benefit is created,and the expectation of society is rewarded to the maximum.